FOCUSES ON PLASTIC INJECTION AND MOLD DESIGN.

DONGGUAN LONGKE ELECTRONIC TECHNOLOGY CO., LTD.

Focus on R & D, production and marketing of precision connectors, electronic connecting lines, metal stamping, mold design

Enterprise mailbox

sales@longke-china.com

NEWS

FOCUSED ON CONNECTOR

主页 > Home > News > Knowledge Encyclopedia >

Knowledge Encyclopedia

USB connection technology for automobile

- Release date:19-10-23 10:17

- Clicks:53

Central topic: the basic principle of USB connector used in vehicle test and identification solution of automobile USB connector: impedance range (90 ± 15%) propagation delay (< 26ns), propagation delay difference (< 100ps), attenuation rate (< 5.8db, f = 400MHz), shielding range (minimum 20dB, 30mhz-1ghz) USB (Universal Serial Bus) is gradually developing into a standard transmission protocol. There is no doubt that this development benefits from the extensive application of USB interface in many electronic products. Therefore, it is a very reasonable and wise choice to configure this kind of general bus equipment on the vehicle.

In the past decade, the application of integrated communication technology in all kinds of vehicles has developed rapidly. The automobile radio device has undoubtedly become the "main unit" in the automobile, which is responsible for the central coordination of a large number of applications and functional equipment.

At the same time, the application scope of electronic products (such as notebook computers, iPods, mobile phones, MP3 players and storage sticks) in automobiles is also increasing. Therefore, it is necessary to ensure the reliability of data transmission between electronic products and existing on-board equipment; in addition, the data transmission system will not only be assembled on medium and high-end and luxury vehicles, but also gradually develop to On standard configuration vehicles, this has become the current mainstream trend.

USB is gradually developing into a standard transmission protocol. Although a large number of relevant transmission accessories have been provided in the market, especially in connection technology (such as connectors and transmission lines), and these accessories are also very convenient and fast to use, in some cases, using these products will make the application complex and risky.

For the USB interface equipment gradually used in the car, its connectors and cables are often not designed according to the bad environment of the car. Therefore, the simplest circuit design is not necessarily the most successful design.

Loose cables and adapter wires laid on the equipment, especially those with poor shielding, will obviously worsen the electromagnetic condition inside the vehicle.

Based on many years of mass production experience, Tyco Electronics believes that these product designs must also meet many other boundary conditions in vehicle use, including very harsh environmental requirements, such as under vibration, humidity, gas pollution and mechanical stress, relevant components must be able to operate normally within the specified temperature range. These requirements will ensure that the relevant parts of the vehicle have a service life of about 15-20 years.

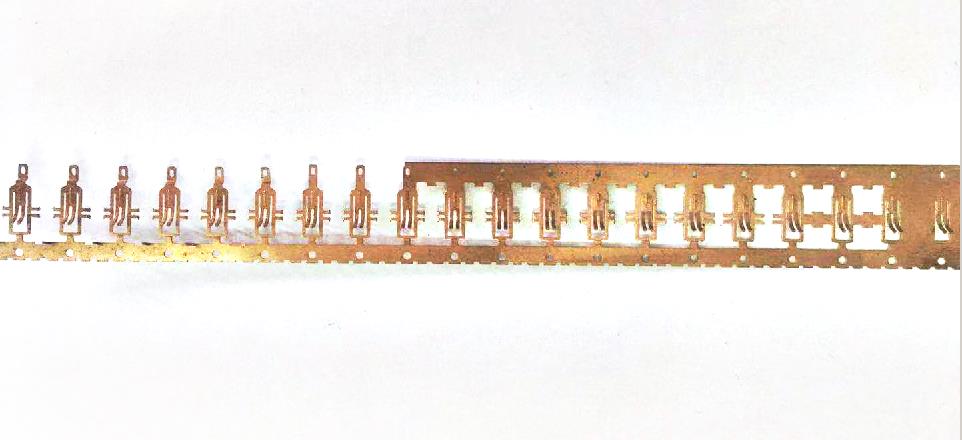

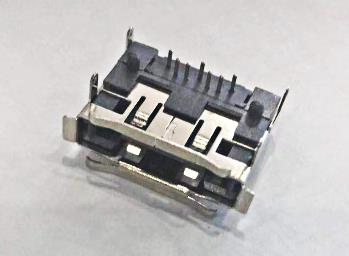

Of course, these functions are also directly related to automobile manufacturers; in addition, the number of plug-in use is also a very important indicator of USB connector. Although many electronic products such as mobile phones and computers need to be replaced every two or three years, it is estimated that the USB interface for vehicles must be able to guarantee 20000 times of plug-in in in the service life of about 20 years. Figure 1 shows Tyco Electronics' reliable USB connection technology for cars.

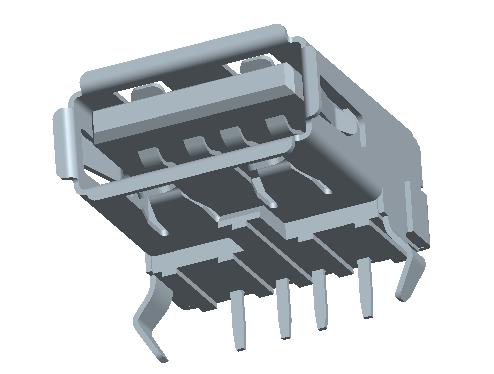

In the next few years, the interface will be miniaturized, so it's only a matter of time before miniaturized or micro USB interface is used. Tyco Electronics solves these problems through a comprehensive product concept, the principle of which is to use connectors and cables that are fully compatible with vehicle use, combined with a flexible USB adapter.

Basic principle of high speed connector used in vehicle

In the development of high-frequency vehicle connection system, the design of accuracy, mechanical strength and overall applicability should be considered. In order to realize the non-interference data communication of symmetrical high-frequency electrical signals through cables and interfaces, the following characteristics are also very important: constant impedance on transmission lines; small dielectric loss of insulating materials; good low resistance terminal connection for connectors; regular twisted pair of signal wires; repeated coverage of shielding part.

It is clear that these special requirements will not be met without additional efforts. At the same time, we must also note that some conditions are contradictory. More importantly, how to choose the terminal connection system, it must be able to ensure good termination within the service life of the vehicle. Possible problems include low contact resistance and impedance, and homogeneity of the plug-in area of the socket and terminal contacts.

For the above reasons, Tyco Electronics selects MQS (micro quadlock) terminal connection series for data transmission. The system has been verified in various vehicles for many years. If it is equipped with symmetrical connector design, it is also suitable for data transmission in principle. The top half of Figure 1 shows a 4-bit shielded connector system based on MQS connections.

In the past decade, the application of integrated communication technology in all kinds of vehicles has developed rapidly. The automobile radio device has undoubtedly become the "main unit" in the automobile, which is responsible for the central coordination of a large number of applications and functional equipment.

At the same time, the application scope of electronic products (such as notebook computers, iPods, mobile phones, MP3 players and storage sticks) in automobiles is also increasing. Therefore, it is necessary to ensure the reliability of data transmission between electronic products and existing on-board equipment; in addition, the data transmission system will not only be assembled on medium and high-end and luxury vehicles, but also gradually develop to On standard configuration vehicles, this has become the current mainstream trend.

USB is gradually developing into a standard transmission protocol. Although a large number of relevant transmission accessories have been provided in the market, especially in connection technology (such as connectors and transmission lines), and these accessories are also very convenient and fast to use, in some cases, using these products will make the application complex and risky.

For the USB interface equipment gradually used in the car, its connectors and cables are often not designed according to the bad environment of the car. Therefore, the simplest circuit design is not necessarily the most successful design.

Loose cables and adapter wires laid on the equipment, especially those with poor shielding, will obviously worsen the electromagnetic condition inside the vehicle.

Based on many years of mass production experience, Tyco Electronics believes that these product designs must also meet many other boundary conditions in vehicle use, including very harsh environmental requirements, such as under vibration, humidity, gas pollution and mechanical stress, relevant components must be able to operate normally within the specified temperature range. These requirements will ensure that the relevant parts of the vehicle have a service life of about 15-20 years.

Of course, these functions are also directly related to automobile manufacturers; in addition, the number of plug-in use is also a very important indicator of USB connector. Although many electronic products such as mobile phones and computers need to be replaced every two or three years, it is estimated that the USB interface for vehicles must be able to guarantee 20000 times of plug-in in in the service life of about 20 years. Figure 1 shows Tyco Electronics' reliable USB connection technology for cars.

In the next few years, the interface will be miniaturized, so it's only a matter of time before miniaturized or micro USB interface is used. Tyco Electronics solves these problems through a comprehensive product concept, the principle of which is to use connectors and cables that are fully compatible with vehicle use, combined with a flexible USB adapter.

Basic principle of high speed connector used in vehicle

In the development of high-frequency vehicle connection system, the design of accuracy, mechanical strength and overall applicability should be considered. In order to realize the non-interference data communication of symmetrical high-frequency electrical signals through cables and interfaces, the following characteristics are also very important: constant impedance on transmission lines; small dielectric loss of insulating materials; good low resistance terminal connection for connectors; regular twisted pair of signal wires; repeated coverage of shielding part.

It is clear that these special requirements will not be met without additional efforts. At the same time, we must also note that some conditions are contradictory. More importantly, how to choose the terminal connection system, it must be able to ensure good termination within the service life of the vehicle. Possible problems include low contact resistance and impedance, and homogeneity of the plug-in area of the socket and terminal contacts.

For the above reasons, Tyco Electronics selects MQS (micro quadlock) terminal connection series for data transmission. The system has been verified in various vehicles for many years. If it is equipped with symmetrical connector design, it is also suitable for data transmission in principle. The top half of Figure 1 shows a 4-bit shielded connector system based on MQS connections.

- 【Printing】

- 【Collection】

- 【Return】

相关产品RELATED PRODUCTS

Address: No.28, southwest Lang Road, Henan Industrial Zone, Jinxia, Chang'an Town, Dongguan City, Guangdong Province