FOCUSES ON PLASTIC INJECTION AND MOLD DESIGN.

DONGGUAN LONGKE ELECTRONIC TECHNOLOGY CO., LTD.

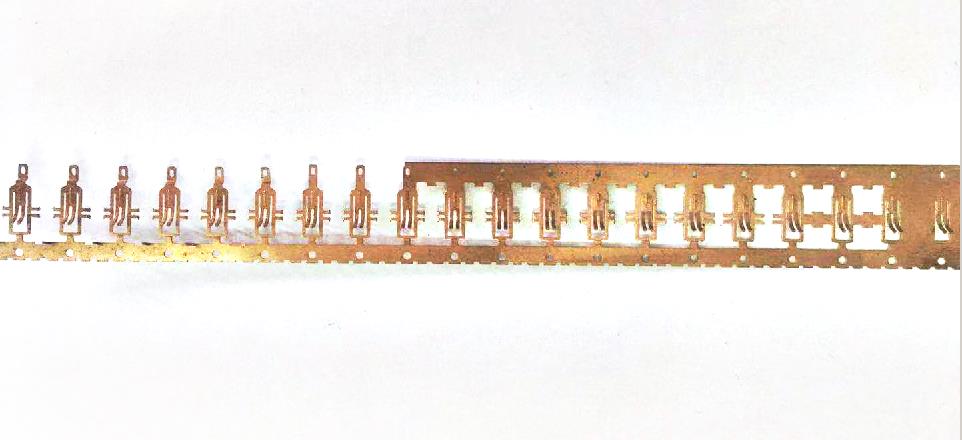

Focus on R & D, production and marketing of precision connectors, electronic connecting lines, metal stamping, mold design

Enterprise mailbox

sales@longke-china.com

NEWS

FOCUSED ON CONNECTOR

主页 > Home > News > News and information >

News and information

Great changes in RF connector will greatly increase

- Release date:19-10-23 09:37

- Clicks:71

On the face of it, RF and microwave connectors don't seem to matter much compared to their high-profile counterparts. Whether high-key or not, RF connectors for wireless communication applications are becoming the focus of attention due to the following reasons: the reduction of size and weight, better overall performance, easy installation, and finally, but also important is to reduce the adverse side effects of RF signal generation, that is, passive intermodulation distortion (PIM) caused by connectors.

Now, after generations of RF engineers and technicians using the same type of connector, a new type of connector is coming out, which will replace the connectors in base station, small cell, distributed antenna system, WiFi hotspot and other applications. In short, as confirmed by market analysts in the RF connector industry, the industry will show a significant growth trend.

According to bishop & Associates analysts, the global RF connector market has exceeded $3 billion and has grown at an average annual rate of 10.8% since 2002, mainly driven by the wireless communication, defense system and telecommunication and data communication markets. One of the biggest driving factors of its high-speed growth is the need to reduce its size. It is not only small battery powered equipment, but also involves many application fields such as automobile and medical treatment. Ejl wireless research is also studying the connector market. It is expected that the widely used 7 / 16 DIN interface users will continue to grow, while the new 4.1-9.5 interface and 4.3-10 connector are generally accepted in North America, Europe and many other countries or regions, respectively. These two types of connectors are described in detail later in this article.

Understanding the specific reasons why connectors such as n-type and 7 / 16 DIN, which have been able to provide excellent RF services and microwave applications for several years, will be greatly replaced by these new connectors in the future will help to understand the challenges faced by wireless carriers today and the reasons why they are convinced of the need to replace traditional connectors on a large scale.

Size problem

RF connectors may be small, but if you put enough connectors together, as in a base station, you will find that these connectors and their supporting cable accessories will form a network and be widely accepted. Therefore, if the connector size can be reduced while improving performance, simplifying installation and reducing possible human errors, there is a good reason for replacement. These factors, as well as the reduction of PIM, are likely to cause familiar connector types such as n-type and 7 / 16 din in micro base stations and small cells to be almost or even substantially replaced by smaller new connectors, and this process has begun.

Most components can be used in backplane after reducing the size of connector, which is very important for space limited applications. But even though these connectors may be small enough, they are obviously not enough for wireless carriers that need more space from crowded device shelters. In addition, applications requiring high data rate, such as HD video, require large bandwidth, which is also necessary for the connector to adapt.

Distributed antenna system (DAS) is also the host of a large number of digital, optical and RF connectors, which may be more than 100 in a large installation. It is not feasible to completely replace the connectors in the existing analog DAS system that only transmits RF signals through coaxial cable. Fortunately, this field is developing rapidly, so the new first installation may adopt the latest connectors when the price is appropriate. Cable and telecom companies have deployed hundreds of thousands of Wi Fi hotspots as customer value-added services, which could become smaller new alternative connectors. Another area that may benefit from smaller connectors is the growing large market for portable RF test equipment, which requires not only small size and high performance, but also robust connector design to meet severe field service conditions.

Harm of PIM

Passive intermodulation distortion (PIM) is one of the most destructive drawbacks faced by wireless carriers. PIM not only has diverse sources, but also it is extremely difficult and time-consuming to find and fix this problem. However, with the increasing data rate of the carrier and the continuous use of OFDM and other high-order modulation mechanisms, PIM is not only necessary but also must be eliminated. If you only want to explain the severity of the problem that PIM may cause, it is advisable to assume that the sensitivity loss of 1 dB of the uplink will cause the coverage area to drop by 11%. Understanding PIM is helpful to grasp its essence. Because PIM is a kind of intermodulation distortion (IMD), it's better to start from the intermodulation distortion.

IMD is directly related to the nonlinear performance of active electronic devices. When two or more signals with different frequencies are amplitude modulated, different intermodulation products will be generated at multiple frequencies, not only the fundamental harmonic, but also the sum and difference of frequencies and the product of these differences / sum frequencies. These unexpected radiation will interfere with adjacent channels and even other services operating at adjacent frequencies.

Even though the strength of these signals may be very low, the data communication system of digital modulation is also very sensitive to nonlinearity. PIM reduces the signal interference ratio and limits the coverage area, bandwidth and capacity, so it should be eliminated as much as possible at any time. A recent assumption for wireless carriers is that a reduction in PIM of - 150 DBC is acceptable, but there are indications that a reduction of - 160 DBC or more may be required. This not only challenges connector and other transmission line component manufacturers, but also almost reaches the current PIM test.

Now, after generations of RF engineers and technicians using the same type of connector, a new type of connector is coming out, which will replace the connectors in base station, small cell, distributed antenna system, WiFi hotspot and other applications. In short, as confirmed by market analysts in the RF connector industry, the industry will show a significant growth trend.

According to bishop & Associates analysts, the global RF connector market has exceeded $3 billion and has grown at an average annual rate of 10.8% since 2002, mainly driven by the wireless communication, defense system and telecommunication and data communication markets. One of the biggest driving factors of its high-speed growth is the need to reduce its size. It is not only small battery powered equipment, but also involves many application fields such as automobile and medical treatment. Ejl wireless research is also studying the connector market. It is expected that the widely used 7 / 16 DIN interface users will continue to grow, while the new 4.1-9.5 interface and 4.3-10 connector are generally accepted in North America, Europe and many other countries or regions, respectively. These two types of connectors are described in detail later in this article.

Understanding the specific reasons why connectors such as n-type and 7 / 16 DIN, which have been able to provide excellent RF services and microwave applications for several years, will be greatly replaced by these new connectors in the future will help to understand the challenges faced by wireless carriers today and the reasons why they are convinced of the need to replace traditional connectors on a large scale.

Size problem

RF connectors may be small, but if you put enough connectors together, as in a base station, you will find that these connectors and their supporting cable accessories will form a network and be widely accepted. Therefore, if the connector size can be reduced while improving performance, simplifying installation and reducing possible human errors, there is a good reason for replacement. These factors, as well as the reduction of PIM, are likely to cause familiar connector types such as n-type and 7 / 16 din in micro base stations and small cells to be almost or even substantially replaced by smaller new connectors, and this process has begun.

Most components can be used in backplane after reducing the size of connector, which is very important for space limited applications. But even though these connectors may be small enough, they are obviously not enough for wireless carriers that need more space from crowded device shelters. In addition, applications requiring high data rate, such as HD video, require large bandwidth, which is also necessary for the connector to adapt.

Distributed antenna system (DAS) is also the host of a large number of digital, optical and RF connectors, which may be more than 100 in a large installation. It is not feasible to completely replace the connectors in the existing analog DAS system that only transmits RF signals through coaxial cable. Fortunately, this field is developing rapidly, so the new first installation may adopt the latest connectors when the price is appropriate. Cable and telecom companies have deployed hundreds of thousands of Wi Fi hotspots as customer value-added services, which could become smaller new alternative connectors. Another area that may benefit from smaller connectors is the growing large market for portable RF test equipment, which requires not only small size and high performance, but also robust connector design to meet severe field service conditions.

Harm of PIM

Passive intermodulation distortion (PIM) is one of the most destructive drawbacks faced by wireless carriers. PIM not only has diverse sources, but also it is extremely difficult and time-consuming to find and fix this problem. However, with the increasing data rate of the carrier and the continuous use of OFDM and other high-order modulation mechanisms, PIM is not only necessary but also must be eliminated. If you only want to explain the severity of the problem that PIM may cause, it is advisable to assume that the sensitivity loss of 1 dB of the uplink will cause the coverage area to drop by 11%. Understanding PIM is helpful to grasp its essence. Because PIM is a kind of intermodulation distortion (IMD), it's better to start from the intermodulation distortion.

IMD is directly related to the nonlinear performance of active electronic devices. When two or more signals with different frequencies are amplitude modulated, different intermodulation products will be generated at multiple frequencies, not only the fundamental harmonic, but also the sum and difference of frequencies and the product of these differences / sum frequencies. These unexpected radiation will interfere with adjacent channels and even other services operating at adjacent frequencies.

Even though the strength of these signals may be very low, the data communication system of digital modulation is also very sensitive to nonlinearity. PIM reduces the signal interference ratio and limits the coverage area, bandwidth and capacity, so it should be eliminated as much as possible at any time. A recent assumption for wireless carriers is that a reduction in PIM of - 150 DBC is acceptable, but there are indications that a reduction of - 160 DBC or more may be required. This not only challenges connector and other transmission line component manufacturers, but also almost reaches the current PIM test.

- 【Printing】

- 【Collection】

- 【Return】

相关产品RELATED PRODUCTS

Address: No.28, southwest Lang Road, Henan Industrial Zone, Jinxia, Chang'an Town, Dongguan City, Guangdong Province