FOCUSES ON PLASTIC INJECTION AND MOLD DESIGN.

DONGGUAN LONGKE ELECTRONIC TECHNOLOGY CO., LTD.

Focus on R & D, production and marketing of precision connectors, electronic connecting lines, metal stamping, mold design

Enterprise mailbox

sales@longke-china.com

NEWS

FOCUSED ON CONNECTOR

主页 > Home > News > News and information >

News and information

Types of electronic connector materials

- Release date:19-10-23 09:33

- Clicks:78

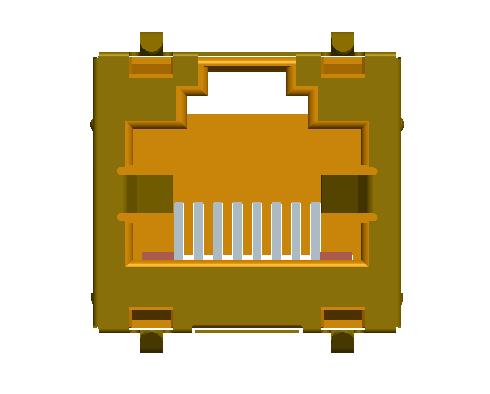

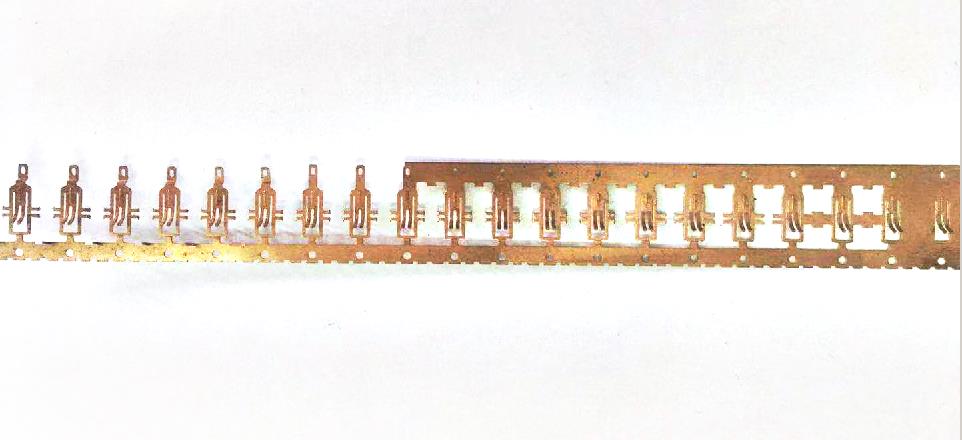

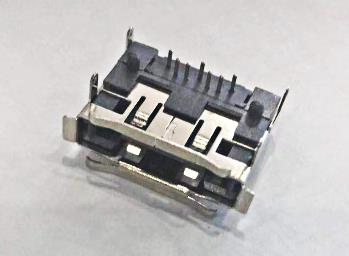

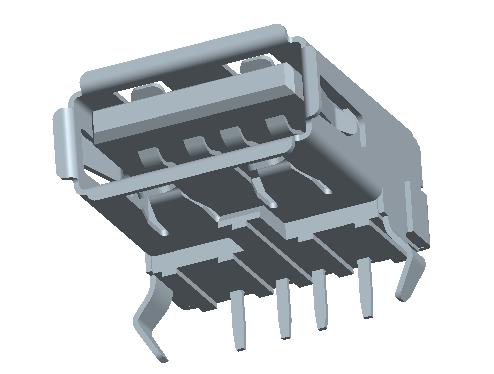

The selection of materials is based on the comprehensive consideration of processing formability, product applicability and strength properties; the cost of electronic connector is different due to the price of materials, processing difficulty and production efficiency; electronic connector materials mainly include insulator materials (plastic materials), conductor materials (phosphor copper, brass); the common engineering plastic materials for electronic connector are LCP. Nylon, PBT.

LCP

It has the advantages of small linear expansion coefficient, low shrinkage of injection molding, very outstanding strength and modulus of elasticity as well as excellent heat resistance, high load deformation temperature, some of which can reach over 340 degrees, LCP also has excellent chemical resistance and air tightness, so LCP material is preferred for general connectors, especially those requiring SMT, eg: Mini PCI Express; DDR.

NYLON

Low cost, high tensile strength, outstanding wear resistance and self sliding, good fluidity, good for thin-wall forming, but serious shrinkage, easy to produce hair, before forming, it needs to be strictly baked to prevent hydrolysis, general connectors, especially dip, are mostly made of nylon material, eg: PCI 120P; PCI Express. PBT

Low cost, high strength, friction resistance, but poor formability, serious shrinkage. Due to the low melting temperature, plastic melting will occur during wave soldering.

LCP

It has the advantages of small linear expansion coefficient, low shrinkage of injection molding, very outstanding strength and modulus of elasticity as well as excellent heat resistance, high load deformation temperature, some of which can reach over 340 degrees, LCP also has excellent chemical resistance and air tightness, so LCP material is preferred for general connectors, especially those requiring SMT, eg: Mini PCI Express; DDR.

NYLON

Low cost, high tensile strength, outstanding wear resistance and self sliding, good fluidity, good for thin-wall forming, but serious shrinkage, easy to produce hair, before forming, it needs to be strictly baked to prevent hydrolysis, general connectors, especially dip, are mostly made of nylon material, eg: PCI 120P; PCI Express. PBT

Low cost, high strength, friction resistance, but poor formability, serious shrinkage. Due to the low melting temperature, plastic melting will occur during wave soldering.

- 【Printing】

- 【Collection】

- 【Return】

相关产品RELATED PRODUCTS

Address: No.28, southwest Lang Road, Henan Industrial Zone, Jinxia, Chang'an Town, Dongguan City, Guangdong Province